Pre-build Foundation Components

There are two types of foundations components:

- ICF components three blocks long & two blocks high;

- Door buck components (located at the footing level);

This section describes the gluing of blocks into components so they can withstand the loads caused by Fastfoot®. This can be done offsite in a warehouse or onsite using a flat working area.

For the design and construction of door bucks, click here.

There are four steps:

- Determine the number and size of foundation components, including door and window bucks;

- Glue ICF blocks into components;

- Attach Side Supports;

- Attach Fastfoot®;

For site installation click here.

Tools

- Flat working area 12' long, 4' wide;

- Hand saw for cutting blocks;

- Quick-Grip® clamps with 12" long 2x4 extensions;

- Drill with hex driver for 1-1/2" x #8 wood screws;

- Foam gun;

Materials

- Low expansion EPS foam glue;

- 1-1/2" x #8 coarse wood screws, 1" fender washers for attaching Fastfoot®;

- Fastfoot® sewn corners, T-junctions and straights;

- MP Side Supports;

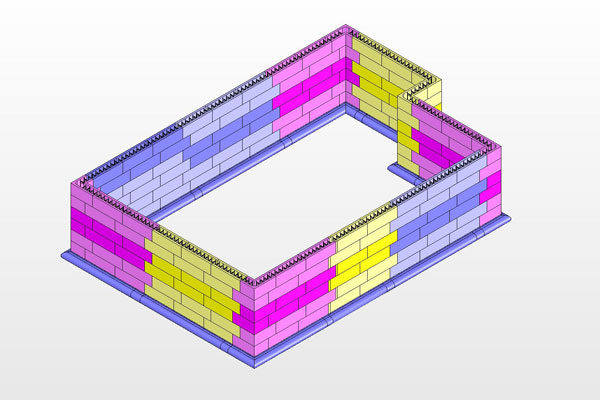

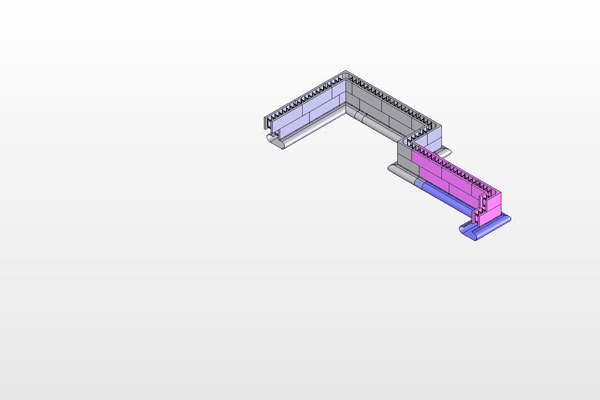

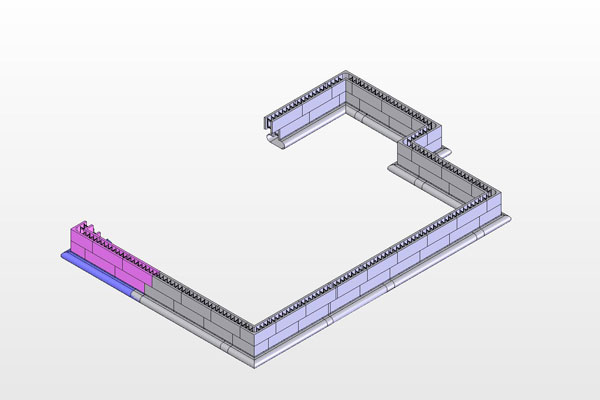

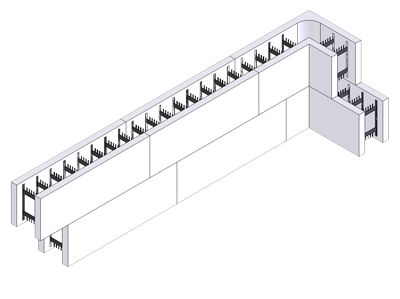

This foundation is built with four corner components and three straight components.

This foundation is built with four corner components and three straight components.

Starting with a standard corner component, and working clockwise.

Starting with a standard corner component, and working clockwise. Next a corner component with a corner offset is placed to the right.

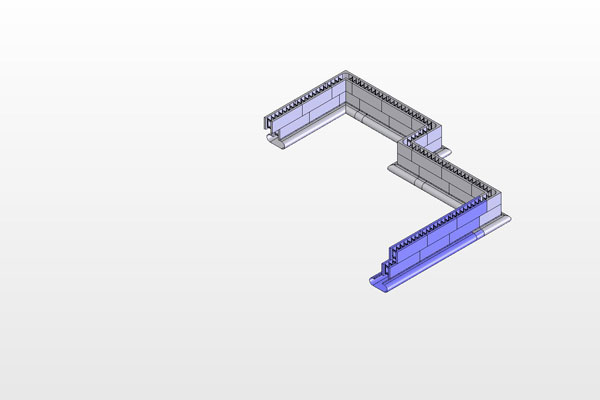

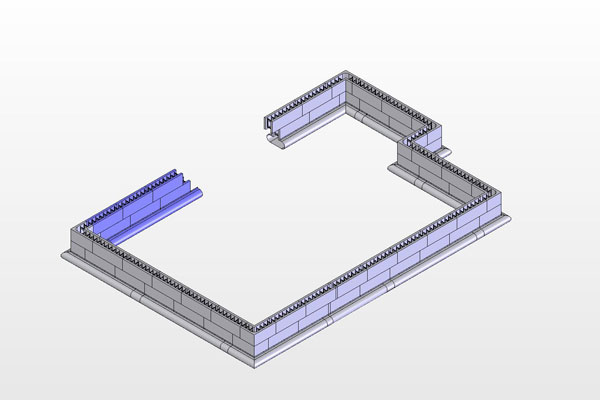

Next a corner component with a corner offset is placed to the right. A standard corner is installed next.

A standard corner is installed next. A 12' straight component is installed.

A 12' straight component is installed. A trimmed straight component is installed to achieve the wall dimension.

A trimmed straight component is installed to achieve the wall dimension. A standard corner is installed.

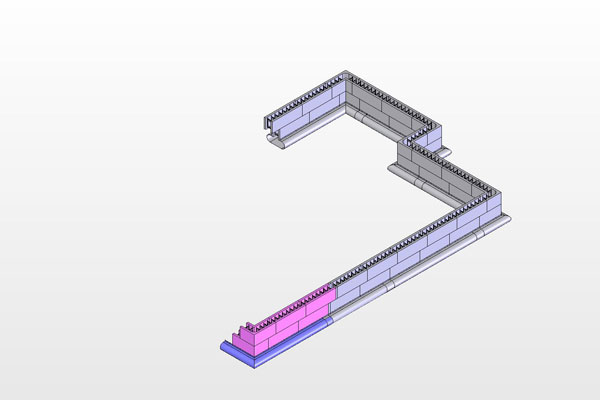

A standard corner is installed. A trimmed straight component is installed.

A trimmed straight component is installed. A standard corner is installed.

A standard corner is installed. Two standard straight components are installed, layer is now complete.

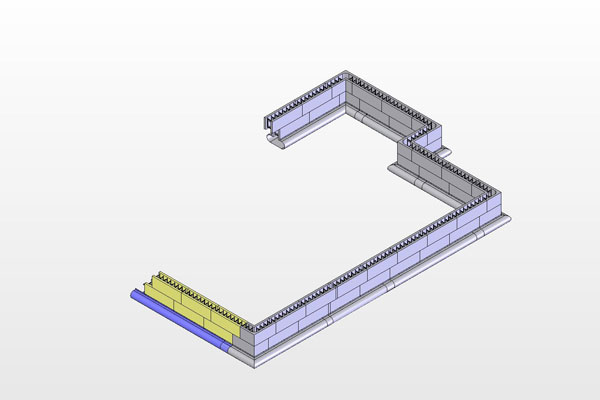

Two standard straight components are installed, layer is now complete. Then next two layers are installed, either pre-built or assembled onsite.

Then next two layers are installed, either pre-built or assembled onsite.

I - Determine Number & Size of Components

There are two types of components:

- Straight

- Corner

Each ICF manufacturer has different block dimensions, so their component sizes vary. Use information from the foundation plan to determine the number of corner and straight components. Trim the component when its length does not match the foundation dimension.

Fab-Form has developed a 3D model for most ICF blocks which creates a detailed drawing showing standard and trimmed components. Should you wish a drawing for your foundation, contact Fab-Form.

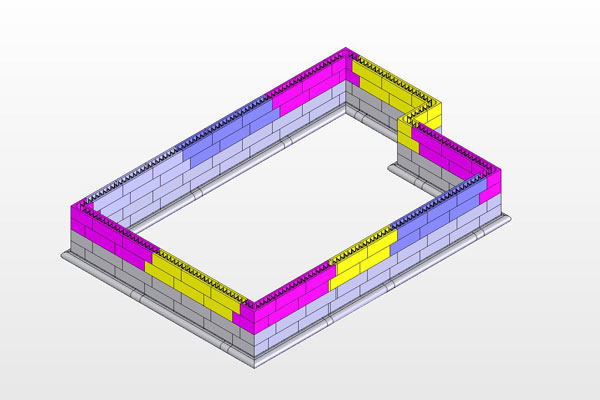

On the foundation to the right, corner components are shown in pink, straight components in blue, and trimmed components (to match foundation dimensions) in yellow.

II - Glue Blocks into Components

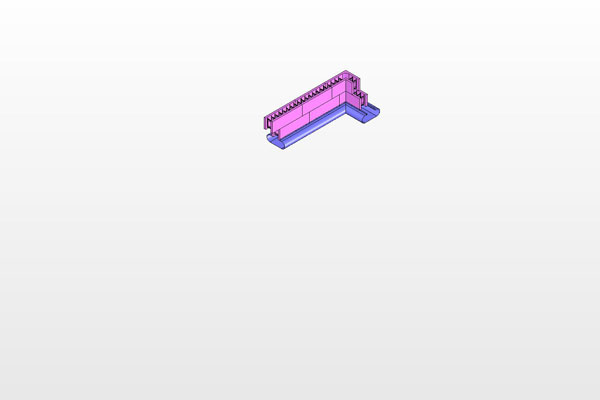

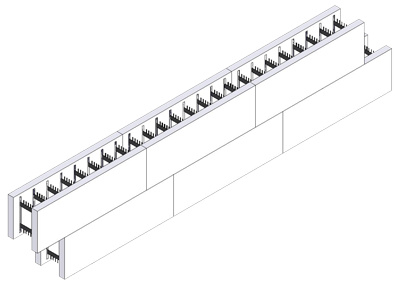

1. Straight Component

Both layers are three blocks long, with the second layer offset two web distances (12" or 16") to produce a 'supporting' and a 'supported end'. Run two small beads of foam glue along horizontal and vertical joints, and clamp as required. Avoid a single large bead of foam as this will open the joint between the blocks.

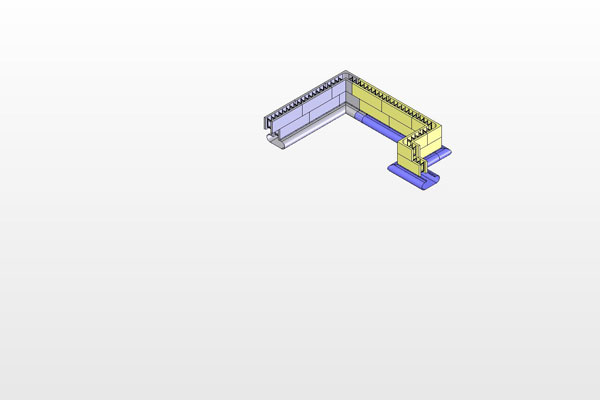

2. Corner Component

The first layer consists of one right hand corner and two standard blocks (to match the sewn Fastfoot® corner). The second layer consists of a left hand corner block and two standard blocks producing a two web offset at each end (12" or 16").

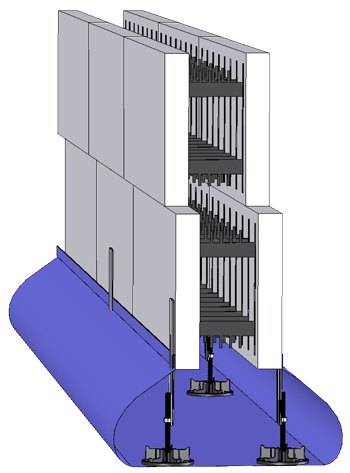

III - Attach Side Supports

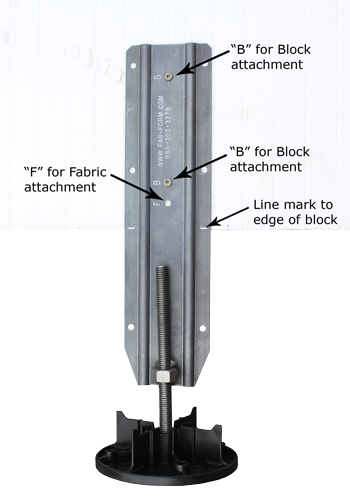

Foam glue the plastic foot pad to the adjusting rod to prevent it slipping off inside Fastfoot®.

Use two 1-1/2” #8 screws through the holes marked "B" (for Block attachment). Use the two horizontal marks on the metal bracket to align with the bottom of the ICF block. The hole marked 'F' is used to attach Fastfoot® to the web.

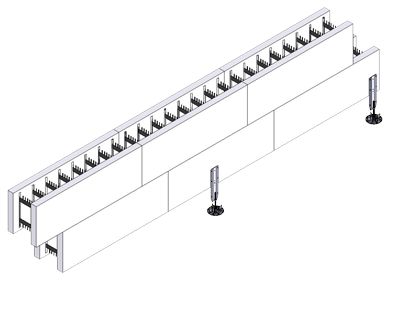

1. Straight Component

Attach a pair of supports at the 'supporting' end extended to the footing height. Attach a second pair at the middle unextended. For custom straight components: if lower level distance is greater than 5', attach one pair of supports; if greater than 10', attach two pairs.

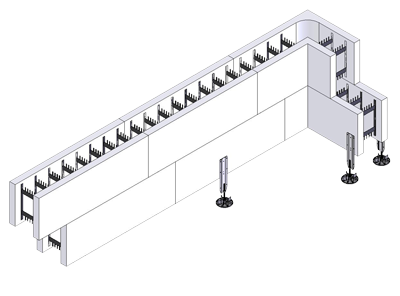

2. Corner Component

Attach one pair of supports under the 'supporting' end, one pair as close to the corner of the component

and one pair 6' from the supported end.

IV - Attach Fastfoot®

Fastfoot® is attached to the base of the ICF block with 1-1/2" x #8 screws and 1" fender washers through each web, either 6" or 8" on center. The fabric is folded outwards and the double thickness attached. Use the calculator below to determine the width of Fastfoot® and the distance from the edge for the fold. If the excavation is out of level, be sure to choose a footing height that covers the deepest section. Adjust the fold line location to accomodate the footing depth at that location.

Corner Components

Fastfoot® sewn corners are available in three sizes: 50", 62" and 74". Screw attach to every web on the inside and outside. The sewn corner is two webs longer than the component at the supporting end to provide an overlap with the adjacent component.

Straight Components

Cut Fastfoot® a two web distance (either 12" or 16") longer than the length of the component. At the 'supported' end, attach Fastfoot® flush with the vertical edge. At the 'supporting' end, extend the fabric a two web distance past end to allow an overlap with the adjacent component.

Click here for site installation.