FAB-FORM MONOPOUR

General Description

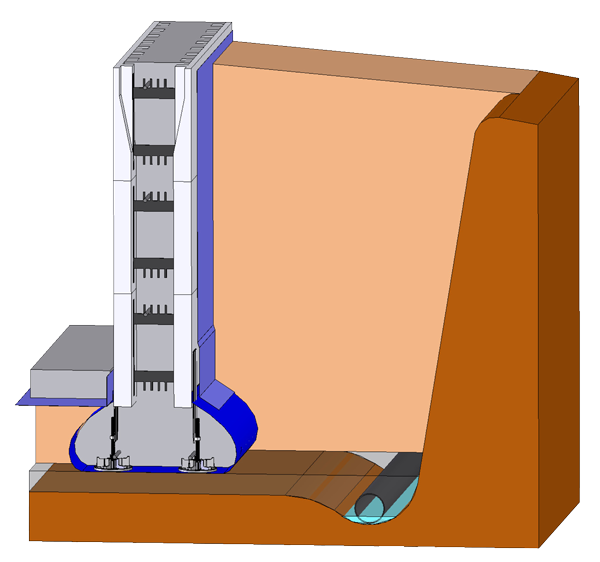

The Fab-Form Monopour System uses the ICF block itself to form the footing, thereby eliminating all footing forming lumber, stakes, cold joint and double pour.

Monopour Supports suspend ICF blocks above the ground at the required footing height.

Fastfoot® is attached to the bottom of the ICF blocks to form the footing. Sewn corners and T-junctions increase speed of site installation dramatically.

Fastfoot® is GreenSpec® listed and Leed® point contributing.

Drill Adjustable Side Supports

Side supports are attached to the outside of the ICF block by screwing to the internal plastic web.

MP™ supports consist of a sheet metal attachment flange, 1/2" diameter adjuster, and an injection-molded foot pad that holds the footing rebar in position above the ground. They are compatible with all horizontal ICF blocks with ties molded into the EPS.

To determine the number of pairs of supports, divide the perimeter distance by 4.

A 6mm ball-hex bit (one included with each box of side supports) is used with a variable speed portable drill for height adjustment. Pairs of side supports are located 4' on center along the foundation wall.

Sizing & Packaging

Standard side support (7" adjuster - for footing depths from 7" to 12"):

- Each side support consists of:

- electro-galvanized flange (screwed to the ICF web)

- 7” adjustable setscrew

- footing pad for support on the ground, 5.4” in diameter

- Each side support weighs 1.0 pounds.

- Each box contains:

- 36 side supports (18 pairs)

- 72 #8 x 1" deck screws (for attaching the MPSSs to the ICF web

- 6mm ball hex drive for adjusting the side supports.

- Box weight: 40 pounds

- Box dimensions: 16" x 10" x 10.5"

Installation Instructions

Load Bearing Capacity of each MPSS

- Each #10 screw has a shear capacity of 150 lbs. going into the ICF web. So the holding power of each MPSS metal flange is 300 lbs.

- The plastic pad has a diameter of 5.4". Assuming the soil has a load bearing capacity of 2,000 lbs per square foot, this means the pad can support 330 pounds load per pad.

- Therefore the capacity of each MPSS is 300 lbs., or 600 lbs. per pair. Note that scaffolding loads do not get transfered to the ICF wall, they go down the strongback directly into the soil. Therefore the only load on the MPSSs is horizontal steel bars (ICF blocks have minimal weight). Assuming a spacing of the MPSS pairs of 4' on centre, the pairs can accept a load of 150 lbs. per running foot of wall.

Sewn Fastfoot® for Corners, T-Junctions, Straight Components

Fastfoot® corners and T-junctions are available in three widths: 50", 62" and 74". To determine the size of footings and corners, go to the footing size calculator available here.

Fastfoot® is custom designed and sewn to fit the components of your project.

Fastfoot® Monopour Library

1 - Footing Detail

2 - Stem Wall

3 - Full Basement

4 - CSI Section Format

4 - Marketing Materials